Acailandia, Brazil-On an August day in the Amazon, when the earth is brown and parched, you can smell this sprawling frontier settlement long before you arrive. Even as the train heaves towards the distant stop, the acrid aroma of charcoal is every where, invading nostrils, clinging to clothing, and even impregnating the clapboard hulls of the shops and homes that flank the main road to town. The skyline is smudged in a permanent dusk of wood smoke and dust, lit only by a ruby moon and the winking blue neon sign of the Santa Maria hotel.

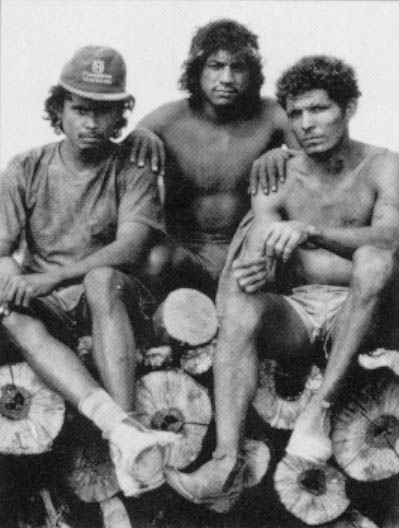

The scrap wood fires that glow in the backlots of local sawmills are partly to blame. But mostly, this ashen ambience is the work of hundreds of kilns, ten-foot tall mounds of brick and clay, that blister the gently rolling landscape like a strange pox. All about, armies of half-clad boys, dusted from head to foot in soot, stack the ovens with lengths of roughly sawn wood.

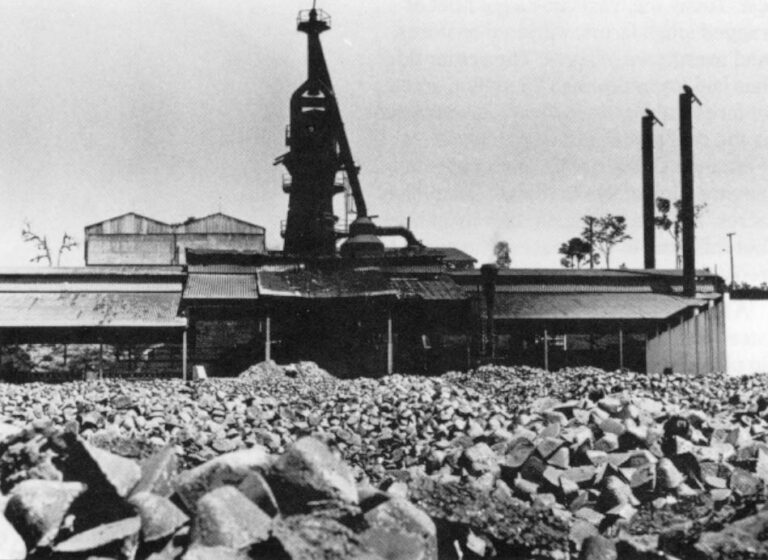

To those who live here, this booming railroad town on the eastern edge of the Amazon region has the whiff of prosperity. The kilns are turning wood from the surrounding forests into charcoal. The charcoal, in turn, fuels the area’s pig iron smelters, which generate steel, revenues, and jobs.

But it also stokes a raging controversy over the destruction of the primary forests of the Brazilian Amazon. Here, according to the world environment movement, the steelmakers are gobbling up the most magnificent of tropical woodlands to make the crudest of metals. Technology from the last centuries, they warn, is turning into problems for the next.

Their protests have grown shrill. Brazil’s outspoken secretary of the environment, Jose Antonio Lutzenberger, has threatened to quit if the pig iron industry advances any further into the Amazon region. The agency he commands, the Institute for the Environment and Renewable Natural Resources, Ibama, has handed out millions of dollars in fines against steelworks for illegal charcoal production and transport. “These companies are technologically backward and bring very little in resources to our state,” charges Violeta Loureiro, head of the Development Institute of Para, a thinktank in the state that harbors two smelters. Abroad, the environmental lobby has pressured European buyers to limit, or halt altogether, purchase of Brazilian pig iron.

The steel companies have launched their own counterattack. Some charge environmentalists with trying to embargo development in the Amazon region. Crusades for preserving the rain forests, they say, are fine for the comfortable classes above the equator but a straitjacket for underdeveloped society. “The debate has grown hysterical,” says Mauro de Almeida, president of the forestry division of Itaminas, a major Brazilian steelmaker with a subsidiary in the Amazon. “And no one even wants to hear our side.”

Indeed, in the fireworks over pig iron, there may well be a good deal more heat than light. Yet sorting out this brawl will be of vital importance. Acailandia lies in the heart of the region planners call Grande Carajas. This is 98,000 square miles, an area larger than Oregon and fully 10 percent of the Brazilian Amazon, girdling a railway that stretches from the Atlantic coast to Carajas, a giant iron mine in eastern Amazonia. The forests fell first here to make way for highways, grazing lands, settlements, and mines. For years, the government waved on the newcomers, lavishing many ranchers and industrialists with attractive tax breaks and credits.

The campaign to repair man’s damage and rein in the rush into the Amazon is also beginning here. Scientists and planners are debating how to recover overgrazed pastures, replant leveled forests, and woo spent soils back to fecundity. These efforts are only in their inkling. But they could be crucial in working out the larger puzzle of Amazonia-how to develop this complex tropical ecosystem without devastating it.

Three decades ago, the region’s only inhabitants were Indians in scattered villages and river dwelling peasants. Isolation ended rudely in 1960, when the government opened the Belem-Brasilia highway, linking the nation’s new capital to Belem near the Amazon delta. A few years later, in 1967, iron ore turned up in the Carajas mountains. A government-controlled mining conglomerate, Companhia Vale do Rio Doce, CVRD, built a city in the jungle and began to plumb the estimated 18 billion tons of 67 percent pure iron ore, the largest known reserves on the planet, and a dozen other precious minerals. The electric company built Tucurui, a 3,800 megawatt generating station, on the Tocantins river, to power a portfolio of megaprojects. More highways followed and, in 1985, CVRD opened the Carajas-Ponta de Madeira railway, hauling iron ore 534 miles from the jungle mine site to a deep water Atlantic port.

There is a bitter irony to the current controversy over Carajas. While many third world governments took fat foreign loans to build bridges to nowhere or monuments to national vanity, the $3 billion mine, funded by the World Bank, Japan, and the European Community, was hailed as a model project. The mine was completed under budget and before deadline. Rarer still, it combined sound finance with sound ecology. A battalion of botanists, ecologists, and anthropologists was deployed to recuperate forests razed by excavation crews, protect watersheds from industrial waste, and insulate indigenous peoples from outright collision with this invading culture of machines and megawatts.

Beyond the company gates is another story, however. Once company officials boldly courted investors by touting the development opportunities along the railway. Now they take pains to distance themselves from the mess without. Even before the railway, the region was already a magnet for problems. But since then, the peasants, prospectors, and ranchers have seared their way through this backlands at a dizzying pace.

As a social gesture, CVRD added a passenger train, charging only a token fare. Now, six times a week, the tattered seats and aisles are jammed for the entire 18-hour ride from the port to the mine and back. The handful of maintenance stops has turned into 18 stations.

Many of the travelers will end up in Acailandia, halfway between the sea and the mine. Though no one has an accurate head count, visitors are proudly informed that in ten years the population here has swelled from about 15,000 to 280,000. This would make Acailandia one of the fastest growing cities on the planet.

The journey here was once a passage through an unsullied landscape, from the unbroken palm prairie to dense rain forest. Today the train runs a gauntlet of ragged small farms, withered pastures, and overgrown villages. The settler tide has laid low more than 25 million acres of forests along the railway, So extensive is the ruin that Brazilian president Fernando Collor de Mello recently announced initiatives to replant 2.5 million acres. Brasilia will again offer incentives, but this time to businesses who agree to replant the forests.

A thornier problem is the arrival of steelworks in the Amazon. Five are now in place and three more being installed along the railway. They currently produce 400,000 tons of pig iron, simple steel used for engine blocks, stoves, and refrigerators, or as an ingredient for finer steels and alloys. Nearly 80 percent of the pig iron is exported to Europe, the United States, and Asia. Though they are latecomers, the steel mills have become the lightning rod for Grande Carajas.

The government and steel executives still defend the program to industrialize the Carajas corridor. (Better, they say, to export value-added manufactures than cheap, raw ore.) However, in the wake of environmental protests and law suits, the grandiose Grande Carajas Program, drawn up behind closed doors by a handful of technocrats and military men, has been scaled back drastically. Early plans spoke of nearly 30 factories of pig iron, iron alloy, metallic silica, and cement, powered mostly by charcoal. But in September 1990, Brasilia cancelled incentives for 21 previously approved projects, including five steelworks.

“Many of these companies were out of compliance,” says Joao Urbano Cagnin, of Brazil’s Office for Regional Development. Urbano says some companies even “sold their incentives to third parties.” No more perks and credits will be offered to Carajas industries, Urbano now insists, unless they plant their own forests for charcoal at least five years before installation. “We won’t approve any industries that can’t present serious reforestation plans.”

This is new talk from Brasilia, the futuristic “Capital of Hope,” raised 30 years ago on a dusty central plateau. Built by president Juscelino Kubitschek, Brasilia was the engine that would move this country “50 years in five,” and serve as a hub for expansion to the hinterlands. In recent jeremiads on the vanishing Amazon, most of the thunder is directed at the Brazilian military, who ruled from 1964 until 1985. The generals did have their own visions of superpowerdom, and taming the Amazon was part of the design. But it was the civilian Kubitschek who in the late Fifties drew and quartered the nation with roads, rails, airstrips, and electricity lines.

The most ambitious of Kubitschek’s ouevre was the Belem-Brasilia, the “highway of the jaguar,” tearing 1200 miles through the backlands. In 1961, Kubitschek matched it with BR-364, a 900-mile road through the western Amazon. He even mounted a bulldozer and personally toppled the last tree that “stood in the way of progress.” Both roads were later paved and became roaring expressways to Amazonia.

Back then, ecology was still mostly a pastime in the northern hemisphere, and scoffed at down south. In the Sixties, after all, Brazil had its own destiny to manifest, and Amazonia was to be the next great pioneer zone, a 20th century reprise of the conquest of California. But the world is tired of that bully talk, now. The vocabulary has changed. Preservation and sustainable development are the order of the day. The Amazon is a frontier out of season.

In a way, the Carajas pig iron industry is a relic of medieval metallurgy. But Brazil has turned making steel from charcoal into a national industry. Almost 35 percent of Brazil’s yearly output of 25 million tons of pig iron, and 18 percent of total crude steel, is made from charcoal furnaces. Everywhere else, coal has long since replaced charcoal.

But, despite their ill fame, the Amazon smelters are not so much predators as scavengers, living off the excesses of a society still relentlessly on the move. In Brazil, writes Claude Levi-Strauss, in his classic Tristes Tropiques, “Agriculture had been a matter of looting for quick profits. Within a hundred years, in fact, the pioneers had worked their way like a slow fire across the State of Sao Paulo, eating into virgin territory on one side, leaving nothing but exhausted fallow land on the other. . . “

The pioneers have reached Amazonia now, and the slow fires are a conflagration. It is the detritus from this settler invasion-logging, ranching, and scorched-earth agriculture-that feeds the Amazon’s smelters. And they can only consume a fraction of the surplus wood; the rest is burned as scrap.

The Amazonian steelworks hardly have a stainless record, however. Last year, Ibama fined one industry 35 times. Another, Simara, closed down early in 1990, due mostly to management problems, but also to the $670,000 it paid for environmental violations. “We have even found Brazil-nut trees in the kilns,” says Norberto Neves, the regional Ibama inspector, referring to the stately nut-bearing tree that is “protected” by the forestry code. In fact, as early as 1965, the forestry development agency required steel industries and saw mills to plant their own forests or pay a reforestation tax. But in the bureaucratic wilderness, violations were either unseen or winked at by officials on the take. Fortunes were paid for forests that never sprouted.

Now, however, the Ibama has cracked down on the outlaws and a major shakeout is likely to hit the pig iron sector. Under the new rules, by 1995, manufacturers will have to supply all their own charcoal, meaning they will have to re-plant vast areas of the Amazon and learn how to log an area without degrading the native forests. The industries are acutely aware of the high stakes. In southern Brazil, steel mills are squeezed between falling pig iron prices and soaring charcoal costs. Smelters now are forced to travel up to 1000 miles to bring their wood from the southern Amazon, where deforestation is still intense. “We are at the end of a cycle of expansion of ranching and extensive agriculture. Those industries who do not plan for this are going to be in trouble,” says Mauro dc Almeida of Itaminas.

Some companies have accepted the challenge. In Acailandia, Vale do Pindare steelworks is working 42,000 acres of a previously logged forest. A small cleared area has been reserved for planting “exotic” species, such as eucalyptus. But most of their efforts are devoted to “forest management,” or the selective logging of successive strips of forest. Cutting crews fell medium-sized trees, leaving a variety of healthy ones for natural regeneration. The cut wood is then hauled out by mules instead of soil-crushing tractors or bulldozers.

In Maraba, the next stop west on the rail, Cosipar, a subsidiary of Itaminas, has also drawn up a detailed forest management plan. But the company is also looking to another novel source of charcoal. Until recently, the 6,000,000 cubic meters of timber drowned in the reservoir of the Tucurui dam, a lake nearly the size of Luxembourg, were chalked up as a loss. But a 58-year-old mechanic, Juarez Crispino de Jesus Gomes, built an “underwater chain saw” and invented the art of submarine logging. Saw mills will exploit the valuable hardwoods. Cosipar is counting on Tucurui’s waste wood to supply half its charcoal needs over the next decade.

Still, turning green tropical biomass into industrial grey steel will put Carajas’ smelters to a severe reality test. The American billionaire Daniel K. Ludwig nearly went broke trying to harvest trees in the Amazon for pulp and paper. But his Jari project survived him, and 23 years later, the 250,000-acre plantation of eucalyptus and pine is producing respectable yields. A search for alternative fuels and methods that spare the forests has also begun. The coconut from the babassu palm, bountiful along the eastern railway, makes a high quality charcoal, though collecting the scattered palm nuts presents a problem. Carajas steelmakers are also studying use of modern blast furnaces that consume 30-40 percent less charcoal.

Some conservationists have called for coal to substitute charcoal. It seems a curious demand. In the last decade, industrial nations have cut back on crude steel production, due largely to decreased domestic consumption and plant modernization-but also to environmental concerns. Charcoal burning does produce its own cocktail of pollutants (tar and toxic gases), but they are more easily, and far more cheaply, controlled than the emissions from the monstrous sulphur-belching coal plants. There is no telling what havoc acid rain and clouds of particulate matter would wreak on the tropical rain forest.

But by far the sorest of controversies is over the plans to harvest wood from native forests, which represent 90 percent of the Amazon. There is little experience in prolonged forest management in the tropics and no guarantees that it can be done without depleting this poly-splendored ecosystem. Some observers are not waiting for the final verdict. “There is no way these forest management schemes are sustainable,” states ecologist Anthony Anderson, who prepared a lengthy report on Grande Carajas for the World Bank. Anderson suspects the pig iron makers are cynically betting on ample supplies of cheap charcoal from bootleg forest cutters and on inspectors looking the other way.

The steelmakers readily admit the risks. “We don’t know how much wood we can produce, or how much it will cost. We don’t know how long the regeneration cycle will be,” says Luis Carlos Vale, forestry consultant for Cosipar. “We will be learning as we go along.” Ecologists may shudder at the prospect of using the Amazon forest as a laboratory. Yet many in the steel industry believe this is precisely Brazil’s unique opportunity. “In a country with vast open areas, plenty of sun, and a hospitable climate, we ought to discuss the possibility of using a renewable natural resource,” says Rudolf Buhler, director of the Brazilian Steel Institute. But lately, discussion has bogged down. “The problem is, environmentalists are talking to environmentalists, and industry is talking to industry,” says Almeida of Itaminas. “Everybody is listening to his own echo.”

The storm over Carajas will likely get worse before it abates. The controversy has forged deeper awareness, but also painful problems. Barreling ahead unchecked, with smokestacks and assembly lines, into the tropical woodlands has costs that could be indelible. Yet turning back the clock of the frontier to some earlier time of sylvan innocence is impossible. In Grande Carajas, the population has swelled from 3,000,000 to 8,000,000 in ten years. Most of the settlers are poor, and many are desperate. Harnessing their environment for tomorrow’s meal is not only a policy dilemma but a commandment. Likewise, declaring a cordon sanitaire and leaving nature to repair itself seems even less plausible. Along the Carajas railway, as in much of Amazonia, the charred and leveled landscape is a mirror that society itself has fashioned. The image of human folly is staring back now, and man, the most reckless of fauna, will have to come up with some answers.

©1991 Mac Margolis

Mac Margolis, a freelance writer and special correspondent for Newsweek in Rio de Janeiro, is researching the Amazon rain forest.