In 1945, a research chemist named Earl Tupper created a drinking tumbler from polyethylene plastic. By 1947, he had developed a way to make plastic containers whose parts would form a firm and virtually impenetrable seal to air and moisture. More than three decades later, worldwide sales of Tupperware exceed $800 million annually.

Tupper’s success played a small part in one of the great growth industries of postwar America: plastics. Its dazzling expansion and gradual maturing are an apt metaphor for the current state of the American economy. Over the past four decades, plastics production grew more than 70 times–from an estimated 568 million pounds in 1943 to more than 37 billion pounds in 1980. But now the frenzy has abated. Since 1978, production has stagnated. Not only are sales flat, but the pace of technological development and future prospects have diminished considerably from a decade ago. The parallel with the economy could not be more striking.

The slowdown is apparent in Wilmington, Delaware at the headquarters of the E.I. duPont de Nemours and Co. For years, it served as the country’s largest explosives supplier. But just before World War II, its research laboratories produced nylon, one of the first of many synthetic chemicals that would, after the war, profoundly influence American industry and lifestyles.

DuPont both propelled and exploited the ensuing boom in new plastics and fibers, enjoying rapid growth and a long succession of highly profitable years. But now, the euphoric expansion has dissipated. DuPont’s laboratories are again searching for a new source of innovation–something to restore the past’s magic.

Its experience is hardly exceptional. America’s postwar prosperity was, in large part, the creature of technology. The roster of major American companies include dozens of firms whose names are virtually synonymous with major commercial innovations: American Telephone & Telegraph (the telephone and transistor); Boeing (commercial jet aircraft); General Foods (quick frozen foods); IBM (the computer); Polaroid (instant photography); RCA (the television); and Xerox (photocopying). These technological innovations largely came to fruition in the postwar era, and the question now is whether the economy can find new growth industries to replace the fatigued pacesetters of the early postwar decades.

That these growth industries played a critical role in the postwar boom is clear. Chemicals, electronics and airlines were among the leaders. They induced new investment and created new jobs. They raised living standards and, with dropping prices, restrained inflation. But it is just as clear that the practical benefits of innovation–higher living standards–have now virtually vanished.

The figures are, by now, familiar. Between 1950 and 1970, the economy’s output–the total of all the goods and services it produced–rose by slightly more than 100 per cent, while the work force rose by about a third. But between 1970 and 1980, output increased only slightly faster than the work force: 36 per cent compared with 29 per cent. Put simply, roughly two thirds of the economy’s growth in the early postwar decades reflected greater efficiency; there was more output per worker and more consumption per consumer. But in the last decade, the increase in the economy’s output almost entirely reflected more people going to work.

To a considerable extent, then, resumed economic advance depends on renewing technological innovation and finding new growth industries. No one knows whether this is possible. So many unforeseen shocks–higher energy prices, double-digit inflation, three recessions–hit the economy in the 1970s that their after effects are still unclear. But to trace the history of one of the postwar growth industries–plastics–is to understand the critical role they played. It is also to understand why, if new growth industries don’t emerge, the next thirty years is likely to be much different from the last thirty.

Life without plastics is, of course, now virtually unimaginable. They touch almost everything: golf–the balls now have a tough plastic covering; trash collection–15 billion plastic trash bags were produced in 1981; automobiles–the auto industry alone consumes one-twentieth of plastics output for everything from paneling to seat foams.

There is no secret why plastics spread so extensively or rapidly. In the uses where they grew fastest, they were usually perceived as being superior, more convenient or less expensive. Consequently, they created new markets or displaced competing materials, such as paper, glass, wood or steel. As late as 1969, 76 per cent of the milk containers consisted of paper cartons; by 1981, cartons’ share had shrunk to 41 per cent and plastics’ had increased to 58 per cent. The plastic containers were stronger, easier to hold, larger and, arguably, more attractive. Plastic wrappers for bread kept out air and water better than paper; the bread lasted longer.

Nor is there much dispute that the substitution of plastics for other materials helped hold down prices, albeit in a modest–and probably imperceptible–way. As output increased, prices generally declined. Companies took advantage of economies of scale and, at the same time, learned newer and more efficient production techniques. Between 1950 and 1970, the prices of plastic resins actually declined 16 per cent, while the wholesale prices of all industrial commodities were climbing 41 per cent. Plastics commanded a significant advantage over increasingly expensive competing materials, like steel and softwood lumber. But, in addition to price, plastics often permitted other efficiencies. Being unbreakable, plastic bottles often allowed faster operation of factory filling machines; being lighter, they were often less expensive to transport.

All this gave an enormous stimulus to investment and job growth. At the base of the plastics industry lie a small number of big chemical companies that produce bulk plastic resins, usually a powder or small pellets. No more than a few dozen companies, operating roughly 400 highly capital-intensive plants and employing roughly 60,000 workers, dominate this business. But on this narrow base stands a big, Byzantine network of small, medium and large plastic manufacturers; these firms take the plastic resins, melt them and then process or mold them into tooth brushes, ice bags, home insulation, floor tiles or food packaging. There are at least 10,000 of these plants, employing nearly 500,000 or about five times as many as in the early 1950s.

Applying Science

Plastics became big business in a largely invisible way. The nature of innovation and its relationship to economic growth are widely misunderstood. The conventional mythology holds that scientific truth, once revealed, leads immediately to new products and processes. But critical scientific advances have often occurred long before they result in useful products. And these products have frequently come from firms that had little, if anything, to do with the original discovery. Creating new knowledge and learning how to apply it are, at times, two distinct activities.

Another popular misconception is that plastic is a uniform substance that has simply seeped into a multitude of different uses. That’s true in the sense that virtually all plastics originate from identical chemical sources–hydrocarbon chemicals, derived primarily from oil and natural gas. But it is false in the sense that dozens of distinct chemicals have emerged from these same origins, many with widely different properties and each with its own peculiar history and applications. Innovation consisted not only of creating these various molecular combinations–called polymers–but also in discovering their characteristics and determining how they could be fashioned into finished products.

The genuinely breathtaking scientific breakthroughs occurred in the 1920s and 1930s. The burgeoning of both plastics and synthetic fibers depended on mastery of the chemistry of polymers–immense molecules composed of a single molecule repeated over and over, often thousands of times, and bonded to each other. Chemists had first begun to understand molecular structure in the 19th century, but their theorizing left conspicuous gaps. In effect, they understood why two substances, if made to react together, might form a third-and entirely new substance.

Giant Molecules

But not all substances could be explained in this manner. In running many reactions, chemists were often left with residues–sticky gums or glues–at the bottom of their test tubes or reaction vessels. These substances did not correspond to any reaction that could be explained with the prevailing molecular theory. The leftovers became a scientific embarrassment, because they seemed to be neither useful or comprehensible. The man generally credited with providing an explanation for this mystery was Herman Staudinger, a German chemist. Staudinger theorized that the puzzling substances consisted of giant molecules that were, in turn, made by many identical smaller molecules attaching themselves to each other. But Staudinger was widely disbelieved, because, in part, his theory implied that his substances of giant molecules (polymers) might have dramatically different properties than a substance composed of similar unlinked molecules (a monomer). This seemed implausible.

As it happened, the first convincing confirmation of Staudinger’s theory occurred at DuPont. In 1928, the company had hired a brilliant young Harvard research chemist, Wallace Carothers, to probe the structure of the mysterious substances. Carothers set out to verify Staudinger’s hypothesis. What Carothers did was to create–or synthesize–a polymer by reacting an alcohol and an acid. Scientists understood simple acid-alcohol reactions; they usually created a new chemical and gave off water. It was also possible to measure crudely the molecular weight of the resulting chemical and the volume of water; in molecular terms, the ingredients and the final products equaled each other. When, under different temperature and pressure conditions, Carothers performed a similar reaction–also giving off water and creating a new substance–he could demonstrate that the molecular arithmetic of the new substance was consistent with the creation of a polymer.

What Carothers and Staudinger had done was show that a huge number of new chemicals might be created. By demonstrating the nature of polymers and how they came into being, they opened a new vista for chemists. Herman Schroeder, a retired DuPont research scientist, aptly calls it a “new civilization.” Literally thousands of new polymers might be created.

All that remained was the immense job of exploring and exploiting the new civilization: of creating new polymers; of discovering their properties; of devising ways to make them; of matching the polymers with practical applications; and of converting the world to these new products. The first useful product to emerge from Carothers’ research was neoprene, an artificial rubber which DuPont began to sell in 1931. Though the costs exceeded natural rubber’s, it also had properties–high heat resistance, a low permeability to acids–that made it exceptionally valuable in stressful uses; hoses in automobile engines were an early application. At times, the research attained an almost magical quality. Schroeder describes the moment of recognition of nylon’s value:

By 1934, they had nylon. Julian Hill ran the polymerization. They got a nice clean chunk of what looks like a melting wax and melts at about 400 degrees Fahrenheit. Julian warmed it up, touched it with a stirring rod and pulled the rod away. Instead of getting a chunk on his rod, he got something like a strand. When you draw it, it stretches and the molecules are pulled out and oriented. They lined up, and it was very, very strong.

The resulting development work engaged a massive amount of new technology. Bringing a new plastic or fiber to market is a long, often tedious and exasperating process. Because so many polymers are possible–and because slight variations in structure can result in different properties–an enormous number of varieties need to be tested. And synthesizing the polymer in the laboratory is only the first step. The plastic may prove difficult to manufacture, touching off a search for ways to make it easier.

What ensued was often a hit-or-miss affair, a series of repetitious experiments designed to discover which changes worked and which didn’t. “You just groped your way to solutions–sort of the way you learn how to play golf,” said George Franta, another former DuPont scientist. “At this stage of the game, you couldn’t separate R&D (research and development) from manufacturing. They have to be very close.” So there was a constant evolution as the polymers were changed and improved.

TEFLON, the trademark for a plastic first discovered by DuPont in the late 1930s, was a good example. It had some exceptional characteristics: it did not melt at high temperatures; it was tough; it was also extremely smooth (the “no stick” qualities that would become famous when it was used in cooking ware). But these advantages came with drawbacks. Because it didn’t melt, it was difficult to process: that is, it was difficult to get the plastic onto anything or to shape it into a product. DuPont kept tinkering with TEFLON. Finally it devised one that can be melted for processing. One new application is wiring for commercial office buildings; the fire resistant TEFLON insulation eliminates the need for running wires in fire-proof conduits, at a cost saving (according to DuPont) of 20 to 80 per cent.

So versatile were the new polymers that they found their way into a large array of goods: detergents, paints, pharmaceuticals and fibers as well as plastics. Nylon stockings, first introduced in 1939 and reintroduced after the war, became an instant success; they were considerably less costly and more durable than silk. The proliferation of synthetic fibers provided the most dramatic example of how new materials reduced costs and raised living standards. Between 1940 and 1979, per capita use of all fibers–not only synthetics, but also cotton and wool–rose 60 per cent, but Americans were spending proportionately less on clothing: about 7 per cent of family budgets in the 1970s compared with 11 per cent in the late 1930s. In 1940, cotton represented four-fifths of all commercial fibers; by the late 1970s, synthetics were three quarters of the total.

Plastics’ inroads came more slowly. In part, the soaring demand for synthetic fibers preempted early investments in synthetic resins. In part, products made with plastics were more novel and encountered stiffer consumer resistance. The experience of chemist Tupper demonstrated the problem. He initially marketed his kitchenware through department stores, but sales were disappointing. By contrast, a small group of direct sales representatives, giving personal demonstrations to potential customers, did much better. Tupper concluded that the plastic containers were unfamiliar and needed explaining. In the department stores, where they were only one of hundreds of products, they got lost. In 1951, after consulting with his original 12 sales representatives, he decided to shift entirely to direct selling.

Other uses emerged only after similar fumbling. In 1947, Max Brunk, a marketing professor at Cornell University’s College of Agriculture, began searching for ways to increase apple sales. “When research started,” he wrote later, “nearly all apples were sold in bulk displays. The shopper had to wait for a clerk to help bag up (the apples), weigh and price and mark her purchase.” One variation Brunk tried was a pre-priced five pound polyethylene bag of apples. Sales rose sharply, from 11 pounds per 100 customers to 24 pounds, apparently because shoppers found the bags quicker and more convenient. By the early 1950s, an estimated two thirds of the fresh apples in New York state were being sold in plastic bags. Later, other fresh fruits and vegetables were marketed the same way.

With time, applications for plastics multiplied. During the war, a variety of plastics had been used for wire insulation; this became a major market, displacing cotton and rubber insulation. Some small plastic firms began selling large see-through polyethylene bags to dry cleaners for their customers’ clothes. DuPont was making plastic tooth brushes and hair brushes with nylon bristles. Ideal Toys introduced plastic dolls and advertised them as more life-like; in the mid-1950s, the firm added the giant, plastic blow-up Joe Palooka punching bag. In the 1970s, polyvinyl pipe for construction became a big market; sales more than tripled. Polyurethane foams appeared in bedding and car padding. Plastic shopping bags displaced paper.

The multitude of possible applications, combined with the rising demand and the number of potential polymers, virtually assured that the industry would become diversified and fragmented. Companies adopted different corporate strategies. DuPont prefers to concentrate on relatively more sophisticated and expensive plastics, where the need for R&D is greater and where the competition–once a new plastic is developed–is less. Of the 34 plastics it now makes, it says it originated 13 of them and is the largest producer of 11 (the two groups overlap). It deliberately refrained from producing some basic plastics, because it felt that these would be widely manufactured and profit margins would be low.

There are some conspicuous examples of big chemical companies that decided to manufacture consumer products. Both Union Carbide and Mobil make trade-marked trash bags–the Glad Bag and Hefty. But, in general, it is simply impractical for the bigger companies to service the huge number of end-use markets. Bottles come in dozens of sizes, shapes and thickness. Transporting them long distances “shipping air,” as it’s called–isn’t economical. “You can’t be all things to all people,” said Roy L. Schuyler, a retired DuPont vice president. DuPont ultimately sold its toothbrush operation. “There are toothbrush manufacturers all over the country who make them at lower costs than DuPont could do it.”

So plastics became one of those flourishing markets where the word entrepreneur has real meaning. Lots of money could be–and was–made by anyone shrewd (or lucky) enough to identify new uses and find the financing to start a new company. The personal fortunes produced by plastics have probably accrued disproportionately to the owners of (relatively speaking) small firms. Earl Tupper sold his company to Rexall Drug in 1958 for more than $4 million worth of Rexall stock. The equivalent value today would exceed $12 million. At plastic industry conventions, outsiders have noticed an interesting contrast between the executives of large companies that produce the resins and the owners of the smaller processing companies that use them; the former tend to dress more conservatively and spend less lavishly.

“There’s a whole history of luck–of being at the right place at the right time,” Howard Samuels recalled. “It was growing 20 to 25 per cent a year.” Just out of the Army, where he served on General Patton’s staff, Samuels and his brother started a new company in 1946. Their father provided the initial $20,000 in capital by borrowing against his life insurance policy. The company, Kordite, initially made plastic covered clothes lines, whose advantages were that they didn’t rot and could be wiped clean. They then diversified into polyethylene bags for food and for dry cleaners. The company was sold for what Samuels remembers as $10 million to $15 million to Textron in 1956. (Textron later sold it to National Distillers, which in turn sold it to Mobil Oil.)

Although the mushrooming of small companies almost certainly accelerated the introduction of plastics into new uses, it also meant that the quality of plastic products was often driven down to the lowest levels that the new technology would permit. If small companies saw markets and profits in inexpensive plastic goods, they made them. If these products proved less than winsome, that was the free market. There were plastic garden hoses that bloated and burst because, not being properly reinforced, they tended to go soft in the sun. There were plastic toys which, when exposed to children, shattered under normal use. There were plastic combs whose teeth broke off. Plastics acquired a reputation for being “cheap” and unreliable–a reputation that remains and still rankles many in the industry.

The image is no longer accurate. New polymers have given plastics sufficient strength and toughness to withstand years of grueling use. Consequently, when deciding on the material for a new component, auto companies can now compare plastics with steel and aluminum. The same rivalry applies to other areas: containers (plastic bottles compete against glass and metals); construction materials (plastic pipes and paneling compete against metals and other composite materials); packaging (plastics competes against paper and tin foil). The latest combat is for domination in the grocery bag market, where plastic is attempting to dethrone paper. For supermarkets, the competition is glorious; it allows them to play plastic and paper companies against each other.

Prisoner of the Economy

Paradoxically, though, plastics’ very success has diminished its role as a growth industry. When plastics’ use was relatively small, the industry’s expansion dramatically outstripped the rest of the economy’s; plastics were creating new markets or stealing old ones from rivals like paper and steel. If the economy went into a slump, plastic sales might still increase because they were substituting for, say, paper sales. But the more plastics has captured new markets, the more it has become a prisoner of the general economy. When all dry cleaning bags are plastic, then increased demand for plastic cleaning bags tapers off. Plastics’ deep penetration into the housing and auto markets has meant that its growth now fluctuates increasingly with the fortunes of these industries.

Many of plastics’ exceptional advantages have also faded. The huge run-up in oil and natural gas prices in the 1970s ended the era of declining plastic prices. This was not a fatal wound; competing materials–glass, steel–also experienced sharp price increases. Moreover, the small proportion of oil and gas claimed by plastics and the high value of the finished products means that there is no immediate threat from a shortage of essential raw materials. But, combined with diminished improvements in manufacturing technology, higher energy prices meant that plastic prices have behaved much more like prices in the rest of the economy. Indeed, in the 1970s, plastic resin prices increased more than average industrial commodity prices–about 200% compared with 150%.

An additional problem involves the increasing expenses of coping with the industry’s social costs. Beginning in the late 1960s, government legislation and regulation forced the chemical industry-of which plastics is but a part-to pay greater attention to the problems of air pollution, toxic wastes and worker safety. In plastics, two widely used monomers (vinyl chloride and acrylonitrile) were found to be associated with cancer; protecting workers meant significant extra expense to reduce exposure levels. The cumulation of these costs is considerable.

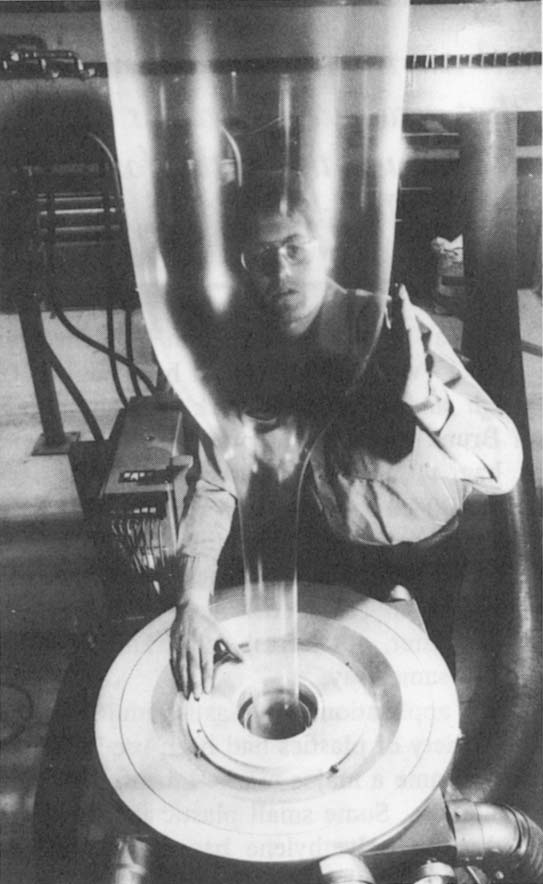

Finally, the maturity is also technological. There is no evidence that the last polymer has been-or ever will be-discovered or that plastics has seen its last boom market. Even now, industry executives look wistfully to increasing their share of auto parts or dominating the grocery bag market. And a visitor to the DuPont research laboratories is shown ongoing experiments with new plastics in a number of high-technology end-uses. In one, DuPont scientists are struggling to perfect new plastics that will lower the cost of water desalinization plants; another project involves the use of plastic membranes in process plants for the production of chlorine and caustic soda, In both cases, finding polymers that will perform their jobs more efficiently is critical.

But even at DuPont, it is impossible not to sense that the most frenetic phase of the plastics expansion has passed. The civilization opened by Staudinger and Carothers has been heavily, if not fully, explored. DuPont has become much more selective in the type of plastics research it will support. “We didn’t plan in 1953. You could just walk into a laboratory and anything you invented would be useful,” recalled William G. Simeral, a DuPont executive vice president. Now the situation has changed. “We have to be much more selective in calling our shots. You can pour money down a rat hole.”

Indeed, plastics and related areas of polymer research fibers, artificial rubbers and paints-is now claiming a decreasing portion of DuPont’s research budget. In 1980, the proportion was half; two years later, it has declined to roughly two-fifths. A new emphasis on “life sciences” is slowly displacing polymer research as the focus for future products. What DuPont hopes will revive its growth is a battery of new chemicals-based in part on genetic engineering-that will be used in food production and health care. Since 1980, research in life sciences has increased from 17 to 25 percent of DuPont’s total.

What is at issue here-for DuPont on a small scale and the American economy on a large one-is the ability to innovate. Most of the postwar growth industries stemmed from innovation: not only the commercial application of new scientific knowledge but also the development of new ways of doing things. The advantages offered by such innovation induced new investment and, based on both lower costs and greater buyer appeal, raised consumer demand. This has not been an entirely painless process. As in plastics, it has often entailed decline in competing industries and unforeseen social costs.

But, on balance, it raised living standards and maintained the vitality and openness of the American economy. If synthetic fibers triumphed over cotton, the essential reason was simple: they were less expensive to produce and seemed to offer superior qualities. If airlines triumphed over railroads, the essential reason was equally simple: they could transport more people, faster, further and cheaper. The ripple effects of these economic upheavals have created personal fortunes as well as replenishing-and depleting-the ranks of American businesses. Rarely has either “big business” or “small business” benefited exclusively. As in plastics, virtually all new industries require a network of suppliers, retailers, wholesalers, distributors, service organizations and consultants that often lend themselves to smaller firms. At the same time, some types of production or marketing in plastics, the production of the resins-are so capital intensive that they can only be handled by large companies.

Innovation has been the germ at the center of this fermentation. It still produces some new growth industries. Microelectronics is the most conspicuous of recent examples. But the questions about the future will not go away; will there be enough of them, often enough?

©1982 Robert J. Samuelson

Robert J. Samuelson, economics reporter for the National Journal, is investigating changes in the US economy since World War II.