LOS ALAMOS, NM–I have successfully infiltrated a government nuclear-fuel reprocessing plant. The next order of business is to steal enough plutonium to manufacture a small, low-yield nuclear weapon.

Getting it out the door is a snap. Despite their expensive detection equipment, random searches and other precautions, the guards are letting me walk off with all I need–just eight kilograms (171/2 pounds).

The last obstacle is the automated accounting system, a small computer that monitors the quantity of plutonium moving through the purification process and records the balance on hand at the end of each shift. Unfortunately for the government, this operation isn’t like a bank where the auditors can count the money right down to the last penny. They’re lucky if they come within half a percent. Consequently, the books never quite balance from day to day. The amount of plutonium in the storage tanks, mixing vats and other plumbing can only be estimated. Fluctuations in inventory are common.

I simply take a little plutonium at a time–quantities small enough to be masked by the normal uncertainties in measurement.

Just to be sure the losses are undetected, I’m secretly checking the results of the daily inventory by tapping into the computer. Whatever charts and graphs the material control office is reviewing, I am also scrutinizing on the screen of a remote computer terminal, modifying plans when necessary.

The first day on the job, I get away with 31/2 kilograms. The computer analysis doesn’t show a thing. I am taking advantage of the accounting system by moving fast; it is most vulnerable before there is enough data for statistical analysis.

For the next two weeks, I take smaller amounts and occasionally put back some plutonium when blue and green letters start appearing on the computer screen to signal possible cause for suspicion. During the third week, I watch helplessly as the frequency and severity of the alarms increase despite three days of no diversions. The computer is collecting more data on fluctuations in measurement and those initial thefts are looking more anomalous. After twenty days on the job, I’ve stolen 5 1/4 kilograms but the statistical charts are now full of orange and red areas indicating high-level warnings. I have been caught.

In the next room a second computer terminal flashes a message of congratulations to David Martinez, the material control officer for nailing another diverter. But no plutonium ever changed hands because this was only an exercise. The whole implausible scenario was played out in a period of 45 minutes using a computer model devised by Martinez to simulate the operation of an actual purification plant. The project is part of a broad, ongoing effort to develop more sensitive accounting methods for detecting the loss of nuclear materials. We never left the gray, one-story, cinderblock structure that houses “Q-4,” the safeguards systems group at the Los Alamos National Scientific Laboratory. The real processing facility, a modern, windowless, concrete building, is located half a mile further up the pinion-covered mesa.

Shortfalls

In this simulation, all the “diversions” were merely instructions to the computer. The mythical guard force and security procedures were deliberately assumed to be unrealistically porous to facilitate this test of the accounting system. In reality, the obstacles to pilfering the raw material for a nuclear weapon would have been considerably greater.

Those other precautions–tight physical security–remain the first line of defense against the theft of weapons-grade plutonium and uranium from U.S. nuclear facilities. But a guard force alone is not enough, no matter how sophisticated. Even the best security apparatus can’t offer much reassurance that thefts have not occurred. Different tactics are required to counter the white-collar threat posed by knowledgeable insiders. Sensitive accounting systems are essential to insure that security procedures and detection devices are working as intended, serving the same precautionary function as auditors at a bank.

Historically, U.S. nuclear facilities have had a troubling record in keeping track of the nuclear materials under their control. Accounting problems have led to well-publicized discrepancies in the inventories at three installations and have fed criticism of the safeguard procedures. In each case, the accounting system lacked the degree of accuracy necessary to allow officials to confidently conclude that diversion had not taken place.

In Erwin, Tennessee, a plant which fabricates highly-enriched uranium to fuel the Navy’s propulsion reactors recorded shortages totaling approximately 250 pounds during the past decade. The controversial facility is operated by Nuclear Fuel Services, a joint venture of the Getty and Skelly oil companies.

Near Aiken, South Carolina, the huge government-owned Savannah River plant has a cumulative shortage of more than 320 pounds of plutonium in its 25 years of operation. The DuPont Corporation runs the reactors and processing unit that manufacture plutonium and tritium for the U.S. weapons program.

At Apollo, Pennsylvania, another plant producing fuel for the Navy lost track of 200 pounds of highly-enriched uranium in the mid-1960s. There have been indications that the Central Intelligence Agency eventually became involved in the case and that material might have been diverted to Israel. The facility, which was owned by the Nuclear Materials and Equipment Company (NUMEC), later was purchased by Babcock & Wilcox Corporation, suppliers of the ill-fated reactor at Three Mile Island.

Official explanations in all three cases contended that the discrepancies were the result of small, unpreventable measurement errors caused by the limitations of the available instruments. Plant operators lacked reliable techniques for doing any better than estimating the minuscule amounts of plutonium and uranium buried with the millions of tons of slightly radioactive waste each year.

These two intractable technical problems–instrument sensitivity and accounting methods–turned out to have profound national and international implications. Together, they form the crux of a bitter five-year-old debate that has paralyzed the U.S. nuclear industry, aggravated relations with major European allies and infuriated dozens of energy-poor countries dependent upon America for supplies of nuclear fuel.

Other factors have contributed to the current dismal state of the nuclear industry: doubts about reactor safety, questions over waste disposal, the precarious financial condition of many utilities and the activities of opposition groups. But the adequacy of safeguards has been the overriding concern in Washington and the principal determinant of recent national policy.

The Carter Policy

Shortly after his election in 1976, President Jimmy Carter was confronted by his advisers on arms control with this unsettling question: if a wealthy, technologically-advanced nation like the U.S. was having so much trouble keeping track of its weapons-grade plutonium and uranium, how could poor, developing countries be expected to do so? At that time, half a dozen nations were on the verge of acquiring large reprocessing and fabrication plants to handle their reactor fuel. These units would have been similar in size and complexity to the Savannah River, Erwin and Apollo facilities where the U.S. was experiencing inventory uncertainties. The prospect of so much uranium and plutonium of exceptional purity being unaccounted for elsewhere in the world raised the specter of some of the material finding its way into nuclear weapons. To Carter, reprocessing of reactor fuel presented an ominous new threat of nuclear proliferation.

In April 1977, he abruptly changed U.S. nuclear policy to halt the spread of reprocessing. Carter placed tough new restrictions on the export of U.S. reactor fuel and nuclear technology. At the same time, he ordered an end to steps at home toward commercial reprocessing of reactor fuel, a move intended to preclude foreign objections that the U.S. was operating on a dual standard or trying to keep this business for itself.

The result was to kill domestic orders for nuclear power plants, pushing the industry further into a tailspin. Utility executives commonly plan their generating capacity twenty or thirty years ahead. Carter’s new policy created widespread doubts about the reactor technology of the future. Caught up in the sweep of events was the nearly completed Barnwell reprocessing plant in South Carolina.

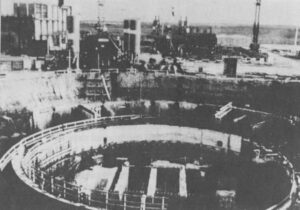

Planning for Barnwell began in the late 1960s, when the reactor business was still booming. The plant was to be the country’s third and largest reprocessing unit, capable of handling all the spent fuel from fifty power reactors. Since then, the owners of the two smaller units have given up on reprocessing because of insurmountable technical problems. By 1976, only Barnwell remained to service the tons of spent fuel piling up at reactor sites around the country. As part of his new policy on non-proliferation, Carter froze the licensing of Barnwell to set an example for other nations. He did not want to be in the awkward position of asking foreign countries to forego reprocessing while the U.S. was still moving in that direction. The Barnwell plant has been in limbo ever since.

So far, Allied-General Nuclear Services (AGNS) has spent $350 million on the project. The company, known throughout the industry simply as “Agnes,” is a joint venture of the Allied Corporation and the General Atomics Company (which, in turn, is owned by the Gulf Oil Corporation and the Shell-Royal Dutch group).

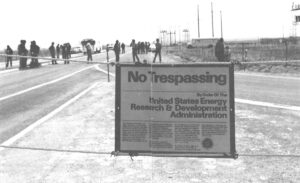

The twenty industrial buildings sit on a 400-acre swath of sand amid the pine forests near the Savannah River in the south-central part of the state. The project has been kept alive, barely, by boosters in Congress who have been able to appropriate about $12 million a year for research activities. Three hundred people now tend to the housekeeping at Barnwell–far less than the 1,500 required to operate the unit. Their changing moods reflect the latest news out of Washington about the future of the plant and their jobs.

Recently AGNS has indicated that it intends to abandon the stagnant investment soon. Earlier this year President Reagan turned down a company suggestion that the government buy the plant. But he added that he is not opposed to reprocessing, hinting that his nuclear policy, when announced, may clear the way for eventual operation of the facility.

In the meantime, the research continues, much of it in conjunction with the safeguards group at Los Alamos. Barnwell has provided the scientists with an extraordinary opportunity for studying safeguards problems. Dr. James Shipley, group leader of the Los Alamos researchers, calls the shutdown in 1977 “a blessing in disguise” in terms of benefits to safeguards development.

Catch-22

At Barnwell, the researchers have the chance to experiment with a full-scale production unit while not interfering with ongoing activities. The work is simplified because the plant is not “hot” with highly radioactive substances. Several times a year, they run the facility with a slightly radioactive surrogate solution of natural uranium unsuitable for nuclear weapons. The computerized accounting system has been developed to the point where it can check inventories with great accuracy every four minutes if necessary. As a practical matter, hourly balances are more useful. Unannounced diversions to test the system at Barnwell routinely are detected within a matter of very few hours.

Shipley now is reasonably confident that his people can design reliable accounting systems for large plants like Barnwell capable of detecting losses smaller than the quantities needed to build a nuclear weapon. Retrofitting the older plants is much more difficult, but dramatic improvement over the existing control and accounting systems is likely.

One obstacle to greatly improved safeguards in this area still remains. “Demonstration is essential,” says Shipley. Nuclear facilities will not operate these days with anything but proven technology.

The future of Barnwell and this safeguards problem are now intertwined in a classic Catch-22. Better accounting methods depend upon their demonstration in an operating plant. At the same time, new operations are stalled, pending the development of more reliable accounting techniques.

If the Barnwell plant is scrapped, the early chance to test the adequacy of the enhanced safeguards system will be lost. On the other hand, proceeding with Barnwell and reprocessing plants like it is foolhardy until a solution to the diversion problem is found.

©1981 Ron Wolf

Ron Wolf, former editor of Straight Creek Journal, lives in Denver, Colorado. He is investigating the safeguarding of nuclear materials in the U.S.